Featured Products

About Us

Welbound

Welbound is synonymous with adhesive binding in India. The group manufactures various machines that complete the post-press cycle from paper folding machines to three knife trimmers. Together with its partners the group delivers technology that converts the printed information into a well bound book

Majority of books made in India has been touched by Welbound - be it in terms of the folding, gathering, hot melt glue binding or trimming

India has a population of 250 million that goes to school. Welbound has partnered with publishers, printers, bookbinders and exercise notebook manufacturers to deliver better bound books

Latest News

From Bengaluru to Meerut: The installation of the Signa gathering system at Arihant Publication India

![]() 22 Dec 2020

22 Dec 2020

In mid-July 2020, Meerut-based Arihant Publication India ordered the Impel-Welbound’s 16-station Signa gathering system, with offline stacking facility, in-feed into the perfect binder Freedom 4K, which is delivered on to a conveyor that could be linked to an inline trimmer. The company already had two six-clamp binders supplied by Impel-Welbound Group, in addition to a number of Muller Martini and Kolbus binding lines. The Signa gathering system was dispatched at the end of August 2020 .gallery-container { font-family: Arial; margin: 0; } .gallery-container * { box-sizing: border-box; } .gallery-container img { vertical-align: middle; } /* Position the image container (needed to position the left and right arrows) */ .gallery-sub-container { position: relative; } /* Hide the images by default */ .gallery-container .mySlides { display: none; } /* Add a pointer when hovering over the thumbnail images */ .gallery-container .cursor { cursor: pointer; } /* Next & previous buttons */ .gallery-container .prev, .gallery-container .next { cursor: pointer; position: absolute; top: 40%; width: auto; padding: 16px; margin-top: -50px; color: white; font-weight: bold; font-size: 20px; border-radius: 0 3px 3px 0; user-select: none; -webkit-user-select: none; } /* Position the "next button" to the right */ .gallery-container .next { right: 0; border-radius: 3px 0 0 3px; } /* On hover, add a black background color with a little bit see-through */ .gallery-container .prev:hover, .gallery-container .next:hover { background-color: rgba(0, 0, 0, 0.8); } /* Number text (1/3 etc) */ .gallery-container .numbertext { color: #f2f2f2; font-size: 12px; padding: 8px 12px; position: absolute; top: 0; } /* Container for image text */ .gallery-container .caption-container { text-align: center; background-color: #222; padding: 2px 16px; color: white; } .gallery-container .row:after { content: ""; display: table; clear: both; } /* Six columns side by side */ .gallery-container .column { float: left; width: 16.66%; } /* Add a transparency effect for thumnbail images */ .gallery-container .demo { opacity: 0.6; } .gallery-container .active, .gallery-container .demo:hover { opacity: 1; } 1 / 27 2 / 27 3 / 27 4 / 27 5 / 27 6 / 27 7 / 27 8 / 27 9 / 27 10 / 27 11 / 27 12 / 27 13 / 27 14 / 27 15 / 27 16 / 27 17 / 27 18 / 27 19 / 27 20 / 27 21 / 27 22 / 27 23 / 27 24 / 27 25 / 27 26 / 27 27 / 27 ❮ ❯ var slideIndex = 1; showSlides(slideIndex); function plusSlides(n) { showSlides(slideIndex += n); } function currentSlide(n) { showSlides(slideIndex = n); } function showSlides(n) { var i; var slides = document.getElementsByClassName("mySlides"); var dots = document.getElementsByClassName("demo"); var captionText = document.getElementById("caption"); if (n > slides.length) {slideIndex = 1} if (n < 1) {slideIndex = slides.length} for (i = 0; i < slides.length; i++) { slides[i].style.display = "none"; } for (i = 0; i < dots.length; i++) { dots[i].className = dots[i].className.replace(" active", ""); } slides[slideIndex-1].style.display = "block"; dots[slideIndex-1].className += " active"; captionText.innerHTML = dots[slideIndex-1].alt; }

Arihant: Meerut’s printer-publisher is India’s pride

![]() 01 Mar 2021

01 Mar 2021

Parvesh Jain (r) with son Atishay (circled) Arihant currently publishes more than 3,000 titles Arihant: Meerut’s printer Parvesh Jain at Arihant, shares the highlights of the past 23 years with Ramu Ramanathan about how the firm is bullish about books Ramu Ramanathan (RR): Let’s begin with the genesis of Arihant’s journey in the heart of the publishing hub of Meerut, which is well known for educational publishing… Parvesh Jain (PJ): Arihant was established by my two brothers and I in 1997. While I oversee the complete printing operation, Deepesh and Reetesh look after content development and sales and finance respectively. RR: Arihant is probably one of the few publishers in the country, which publishes books in almost all the segments of education… PJ: Since our inception with a set of books for IIT JEE in 1997, Arihant currently publishes more than 3,000 titles for engineering, medical, competitive entrances, school curriculum, ITI, polytechnic and government recruitment examinations. RR: What has been the greatest achievement for Arihant thus far? PJ: Every year since 1997, Arihant has managed to venture into new segments in educational publishing. Now, in a short period, we spread our branches all across the country. During that time, printing was outsourced despite having our own book printing press in Meerut. RR: When did you think of consolidating the printing of your publications in different locations? PJ: In 2014, we moved to a 12-acre facility, which housed a factory that could compete with the biggest of book-printers in India. All the capacity that we built up is being used for our publications. RR: Arihant has invested in multiple webs. How did you plan your binding to cope with the bottleneck in post-press? PJ: The binding in our press was initially dominated by the single- and six-clamp binders, and an occasional offline high speed machine. It took some time to graduate to complete in-line solutions, as the workflow, including processing and movement of material, is very crucial. RR: That is when you decided to invest heavily in post-press… PJ: Over the years, the offline binders were replaced with pre-owned European inline binders from Muller Martini and Kolbus. The binding facility now includes an Accoro A5, A7, Kolbus KM 470, complete with gatherers and inline trimmers. RR: Any machinery from Indian manufacturers on the post-press shop floor? PJ: Recently, an Impel-Welbound Bindwel Bindline consisting of a 16-station Signa gatherer and a 12-clamp Freedom 4K binder were added to the above armoury. RR: How did the shop floor workers in the post-press department respond to the new machinery? PJ: Pretty well, judging by the fact that so far, we have produced 10 lakhs books in month since the installation. My team is happy that we made this decision. The Impel-Welbound director Anil Kumar visits us regularly to understand any challenges that we are facing and provides immediate solution. RR: Chasing low-priced manpower has often been touted as a dangerous practice by experts. What is your view? PJ: The more handling one has, between printing and packing plus loading on to trucks, it creates more wastage. The concept of low-cost manpower does not end up being cost effective. This is owing to the fact that the biggest cost in a bindery is manpower. And this is directly related to wastage. RR: This brings us to: inline vs offline. What are the operational benefits? PJ: By linking the process of gathering to finishing the book, we are able to ensure that the mistakes are near-zero, books do not get smeared, turnarounds happen faster, lesser energy is consumed – all of which lead to a better quality at predictable speeds and lower costs. THE IMPEL-WELBOUND PARTNERSHIP Before going in-house with our postpress machinery, all of our jobs were outsourced at shop floors, which had Welbound machines. For us, it meant a natural progression of an association of more than two decades. When Impel decided to move away from its partners in Kerala, to set up a manufacturing in Bengaluru, we were one of the early buyers of machines made in Bengaluru. Welbound Technical Services, its sister concern handled all our installations of imported European binding machines. RR: How do you want to reduce binding time for paperbacks without compromising quality? PJ: Product runs are coming down, even in educational publishing while the number of titles keeps increasing. This means a binder should be able to change over from a given setting to another as quickly as possible. With new machines and affordable automation, this is possible. RR: How often do you review your factory operations? PJ: We have operational reviews on a regular basis. As we handle a wide range of markets the complexities related to paper, sizes, book thickness, runs and turnaround times are huge. We need to be very agile in our planning and operations. RR: Agile is good. But how do you deal with the growth of complexities that accompany the company growth? PJ: There are quarterly and annual management reviews, that discuss everything from the year to date performance, forecast, uncertainties (as we face now), and opportunities. Such reviews help us conclude on the top issues and the top opportunities and then we plan the steps needed for achieving the optimal results. RR: Every time you decide to scale up the operations, there is a cost cycle that you go through… PJ: Despite having a large area for expansion, space is something that needs absolute focus as costs simply follow the increase in it. Year-on-year, if we can produce the same quantity of books at equal or better quality, while consuming less space, energy and manpower, then we have won the game. RR: And how have you managed to achieve that? PJ: From the many ways that we had thought of, one of it was to invest in a Bindwel Bindline, which consumes 35% less space and energy, while delivering the same quantity of books compared to the European binders that we have. RR: Interesting. As a publisher, how do you define long runs/short runs? PJ: We are definitely past the era of printing millions of books of the same title. Only government textbooks have print runs, which notch up in lakhs. While we may have some texts running into such numbers, the runs get reduced by division as the cover could be different and some portions are customised. In education, we consider 5,000 as short runs and 50,000 as long runs. MEERUT – AT A GLANCE The size and stature of the Meerut book industry… Meerut can be called as the Daryaganj of Uttar Pradesh. After New Delhi, Meerut must be the largest publishing printing hub in the country, though Meerut is more popular for educational publishing now. Once upon a time it used to be the pulp fiction capital of the country. One virtue about the Meerut book industry… The city used to be a hub for publishers, writers and artists of Hindi pulp fiction since its inception. Many of these publishers did printing in New Delhi due to the availability of a huge number of printers. Although printing would be in New Delhi, binding used to happen closer to home. At that time, folding was done manually at homes, before they are brought to a hall where gathering and perfect binding would happen. One inside info about Meerut … The fact that Meerut is the most cost-efficient converter of paper into books in India. Many leading integrated print houses in the country have approached publishers in Meerut for print jobs in the past, and have left with the information of our unbelievable cost of conversion. Impact of GST on the printing and publishing book industry in Meerut… GST was not good for the publishing industry, as all the increase associated to that ended with us, publishers. The consumer is not aware of the GST as books are not taxed. The distributer network was not willing to foot the cost. So, in most cases, the publishing industry ended up absorbing the same. RR: With schools and colleges remaining shut during the pandemic, how much has it impacted Arihant? PJ: Business had declined by 40%. However, we expect this segment will be quickly up and running, as we have the schools reopening now. RR: As per market reports, we are hearing that unit sales of books in the first half of 2020 is not all doom and gloom. Is there any uptick of demand? Your view… PJ: Quite true. Except school textbooks, the remaining segments have already picked up steam. And as we hear from the market, in some states such as West Bengal, even school textbooks are being printed. RR: On the other hand, a world which has virtual classrooms and growing unemployment could lead to new trends in publishing. What is the Arihant view on this? PJ: Our view is that online will coexist with classrooms. Content is the king and presentation is its queen. So be it textbooks or virtual classroom content, you have to be ahead of the curve. There are huge business opportunities for print, even in online education. RR: Many publishers have dabbled in to crossover (multimedia) content, but these are generally on the backburner. With the state of education right now, is Arihant bootstrapping some of these solutions? PJ: It is like the physical retail waking up to the new world of eCommerce. Same product is sold, but the rules are different. Once you understand, then bridging the gap will become easier. RR: Along with K-12, there would be a growing audience for skill development content. Are publishers addressing them? PJ: We have lot of content related to competitive examinations addressing employment. They cover basic subjects and special topics related to certain skills. RR: What is the one tough lesson to learn from this pandemic? PJ: Cost cutting. This is not merely on paper, but also in practice. We have no long-term plans for the future; at least for the time being. RR: I see. Let me conclude this interview with my favourite question. What is the one book project, which you produced that was very difficult? PJ: A book called General Studies Manual, which was a 2.75-inch back cut job produced on the Impel-Welbound WB@2500 six-clamp perfect binding machine.

How Shri Balaji added bookbinding to its repertoire

![]() 07 May 2021

07 May 2021

Bharadwaj: “Some of the books have runs that are above one lakh, and sometimes we need to break and continue to produce books in parallel. Every day is a new day in learning” Shri Balaji Publications has been in the news. The publisher-printer has installed an entire range of hard cover machines from Impel in its factory in Muzzafarnagar, Uttar Pradesh. The reason: the two-decade old Shri Balaji Publications produces a wide array of books for various competitive entrance examinations and central boards. In these hard times, they needed a hard cover. The three founders, Ashish Agarwal, Neeraj Bhardwaj, and Prabhat Kumar, also ensure the distribution of these books all over India through their eRetail network since most of these books are prescribed for the CBSE board or for competitive exams. Other than higher education reference books, there are books for competitive exams like JEE and NEET. The book factory, which runs two shifts of eight hours each, has a built-in area of 10,000-sqft. The founders say, “As a publisher, we provide the best quality of content, which helps the students to gain knowledge. We do not compromise in the quality of content and naturally, this gets extended to the print and binding quality. We integrated backward as we were not getting the quality from the market despite willing to pay the price.” That’s how the factory boasts of two WB@2500 and a full range of case-binding machines. This includes the Starplus case-maker, casing-in and joint forming and a Wohlenberg gatherer plus three-knife trimmers. This is backed by a Heidelberg four-colour press as well as three Rota Print web presses. The founders, speaking exclusively to PrintWeek, explains, “Since 2018, the Impel-Welbound team in North India, led by Anil Kumar, has given us great support in our binding unit. We trust its quality and technical support. When we dared to set up our own hard cover binding system, we could not think of anyone else.” The training at Shri Balaji Publications included Impel-Welbound’s top managers, including the division’s CEO Rohin Kumar, visiting the headquarters in Muzzafarnagar. But there is a story within the story. The Shri Balaji team built the factory from scratch in three months. During that period, the machines were installed plus the books were being produced in-house. Neeraj Bhardwaj says, “As publishers, our jobs were outsourced till December 2017. Then, at the start of 2018, we thought of having an in-house printing press.” Bhardwaj continues, “This was a risk, which we took, as this decision was in the midst of our peak academic book season.” When asked why they opted for this disruption, Bhardwaj says, “We took this step because we were not getting the quality in books. Our books were being delayed in the market and we had rejections as these did not meet our quality aspirations.” Beneath the veneer of textbook production, there is a lot of complexity. For example, the books for JEE and NEET require a huge number of versions and revisions. These require complex organisation and need a very agile print production facility. Bharadwaj says, “Some of the books have runs that are above one lakh, and sometimes we need to break and continue to produce books in parallel. Every day is a new day in learning.” The team at Shri Balaji is grateful. Ashish Bhardwaj says, “We had huge support Impel-Welbound that helped us set up and turnaround jobs fast.” rabhat Bhardwaj adds, “We never thought of producing hard cover books in-house. And when we set this up, with the support from Impel-Welbound, the company advised us on everything that can go wrong or right, and we felt confident.” Rohin Kumar, CEO of Impel’s hard cover machines vertical with an automatic case-maker Impel-Welbound partnership The Impel-Welbound group, after establishing and streamlining the soft cover book production in Bengaluru, decided to foray into the hard cover book segment. Suresh Nair, director, Impel-Welbound, says, “In our erstwhile avatar in the partnership with the Kerala-based Intimate Machines Group, we were always focused on soft cover bookbinding. We had internal expertise with respect to application, thanks to our partnership with Henkel Adhesives. We did not look at making hard cover machines as the segment already had a few suppliers clamouring for sales.” Nair continues, “However, every time we were having a discussion with a new customer – usually a commercial printer establishing in-house bookbinding, the requirement used to come up. Even our existing customers complained about the lack of quality hard cover-making equipment. While there were some solutions, the casing-in and finishing operations remained the forte of artisans; or you needed to import machines.” There are top class solutions for book-block making, from companies like Joy D- Sign; but there was a gap when it came to quality solutions for hard cover books. Nair continues, “Instead of starting from the scratch, we teamed up with experts in the field, like Rohin Kumar, who comes with the experience of running a company manufacturing such machines. We gave it the capital and design infrastructure to come up with products that will handle the diverse requirement in commercial printing, be it sizes, material or productivity.” The Impel-Welbound team added after-sales support which included solid training in the technology so that the process becomes fool-proof. Conclusion The unlocking, which began in May 2020, threw up challenges which have not been witnessed before. Availability of material, labour and technical support remained among the top of issues faced by book printing. Machines were stranded without trained manpower or they broke down and refused to work. Rohin Kumar, CEO of Impel’s hard cover machines division, says, “Impel-Welbound differentiated itself by being able to supply raw material, spare parts and after-sales support, just in time despite all the challenges.” He adds, “We had engineers based out of places like Guwahati, Mathura, Kolhapur – and for the customers facing an operational challenge, this was a huge relief. A few customers looked at this as a signal for trying out the hard cover solutions from us. And this resulted in sales to markets like Hyderabad, Vijayawada, Bengaluru, Chandigarh, NCR region and so on.” Kumar signs off, “Quality is part of the Shri Balaji’s eco-system and its takes pride in delivering a book with the right content and quality.” Case in point, a voluminous, two inches plus Physics textbook – Advanced Problems in Physics.

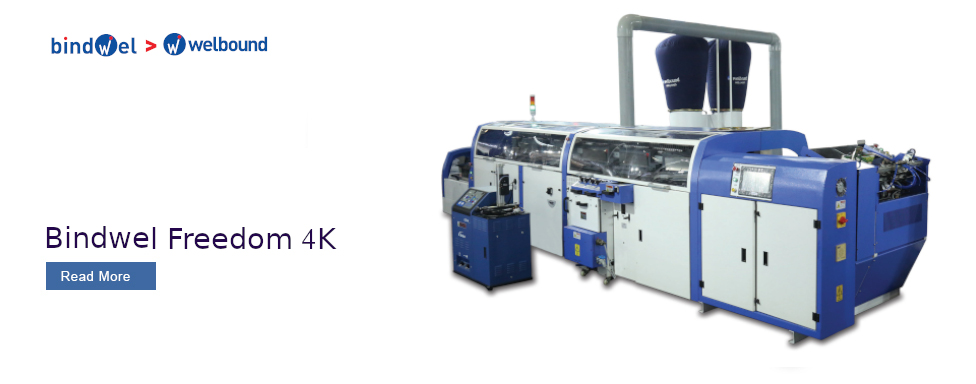

Me & My: Impel-Welbound Bindwel Freedom 4K

![]() 30 Sep 2020

30 Sep 2020

Naresh Chandna, director, Sai Printo Pack Naresh Chandna, director, Sai Printo Pack tells Rahul Kumar his reasons to choose the Bindwel Freedom 4K from Impel-Welbound. Please describe your company. We are an integrated book printing firm with in-house capabilities from design to fulfilment. We address a large variety of publishers from legal, academic, education and trade. We are equipped with both digital and offset printing facilities for both hardcover and paperback production. When did you start using the Impel-Welbound product? We had a single-clamp binder from Welbound long back. We decided to have a look at one more machine from them after Impel broke away from the Trivandrum group and put up its products in the last PrintPack exhibition. We installed the Freedom 4K binder in October 2019. What are the features of the machine you like? Its speed, flexibility, expandability and reliable local service support. Above all, it is future-ready for various gluing technologies. Why did you decide to use the Freedom 4K? We already had a medium speed binder with us, before, that gives about 1,500 books per hour. However, we faced bottlenecks while addressing the changing needs of our customers, be it in terms of turnaround times or quality. Impel introduced us to the Bindwel Freedom 4K machine that can produce up to 4,000 books per hour, and also can be linked to a gatherer and three-knife trimmer. What are the features that tilted the favour in this? Freedom 4K gives you the freedom to add machines before or after it, to complete the line. One can upgrade to PUR binding without any difficulty. Job changeover is fairly easy to handle. It is a modern machine, unlike some of the pre-owned imported models that we looked at, and helps produce high quality books while keeping your operational costs minimal. Its powerful MIS interface gives us timely information on production and costs. How much have these features helped you? We have been able to address our customer requirements better, providing deliveries faster than before. Our customers also have appreciated the quality of ornamental creasing, side gluing and firmly nipped book spines. For what applications is the product used? We use the binder for all our soft cover book production requirements. If there’s a critical post press job that has come your way, would you rely on this to see it through? Yes, of course, with a brand new machine and with the support of capable application engineers from Impel — there will be no concern at all. The advantage of dealing with a forward looking company like Impel is that they do not go only by the specs sheet, and are willing to address some on-the-job issues we are likely to encounter. What’s the quality like? Compared to our earlier process, the spine and side gluing are much better, and so are cover creasing and the firmness of the book spine. How easy is it to use and handle? This machine is ideal for book printers who have production requirement of above 10,000 books per day. As the future is for inline binding — as space, manpower, energy and wastage need to be reduced — this is an ideal machine to invest in. Would you say that it offers value for money? The machine offers a good value for money. Though the investment costs are higher compared to pre-owned European machines, the overall cost of ownership is much lower. Be it energy consumption, space requirement, upgradeability – Freedom 4K stands ahead. Were there any difficulties during the use of Freedom 4K? There are teething issues with any new machine or technology and we faced it in this case as well. The biggest advantage I see is the quick response of the service team and their ability to address the issue without any delay. Who do you think the Freedom 4K is right for? Inline binding has become a necessity and every book printer will need to switch over from the current offline solutions based on the production requirements. Under what circumstances would you recommend it to others? Unless your requirements are short to medium run or if you are in the digital book print business, you will need a machine of this speed and expandability. CONCLUSION User’s verdict Speed ★ ★ ★ ★ Quality ★ ★ ★ ★ Reliability ★ ★ ★ ★ Value for money ★ ★ ★ ★ ★ Supplier’s response Pallippuram Sajith, director, Impel Services (A Welbound Group Company), says, “Bindwel Freedom 4K is a 12-clamp perfect binder which can be connected inline with a gatherer and three-knife trimmer. Freedom 4K occupies the minimum space and consumes lowest energy among the class of binders delivering similar throughput. Be it thin or thick books or a wide range of signatures or covers, Freedom 4K provides optimal quality with minimal wastage. Along with our Signa 4K gatherer and Trimit three-knife trimmer, Freedom 4K establishes the ‘Bindline’ inline soft cover book production system. Sai Print o Pack have always strived to differentiate themselves by delivering good quality binding in tight schedules consistently and Freedom 4K will vastly help them in their core strength.” Contact details Pallippuram Sajith, director Impel Services (A Welbound Group Company) Email: sajith@welbound.com Mobile: +91 93210 86601

SDR Printers: How an education book print factory upped its bindery game by going inline

![]() 28 Feb 2020

28 Feb 2020

(l-r) The nextgen Guptas- Rajiv, Sanjay, and Prashant Seeking flexibility, SDR Printers opted for a Bindwel Freedom > 4K – 12-clamp perfect binder nine months ago. The book printing unit, based in Tronica city, in the outskirts of New Delhi, has been growing at a fair clip and so, new challenges required new solutions. A PrintWeek report. Founded in 1998 by Anil Jain, the offset printing unit located in Nazafgarh Road focuses primarily on large Government tenders, across India, with a specific interest in textbooks. SDR Printers produces educational books for leading MNC and Indian publishers. It provides end-to-end facility, beginning with pre-press to fulfilment. The company kept adding web offset machines to its array of Heidelberg sheetfeds, and did not realise that it was running out of space — space constraints for machines, some manual operations that took up space; and the work-in-progress between the sewing machine and the Welbound six-clamp binder. The family-run company, established by LN Gupta in 1986, realised that it needed to have a long-term plan to service its customers better. And so, the new generation of Guptas — Sanjay, Deepak and Rajiv — got into action. They brainstormed and created a plan, which helped them increase the available space by acquiring a nearby factory and increasing internal efficiencies through replacement of machines. The backbone of the print facility is an eight-colour heatset Heidelberg Harris reelfed machine. This is complete with an inline stacker that bundles the signatures into neat piles that can be transported for signature gathering. Three high-speed folding machines support the four-colour sheetfed presses, three in all, from Heidelberg. Then there are five thread sewing machines which produce book blocks later bound by a six-clamp WB2000 plus an offline Kolbus binder. As most of the books produced by SDR are either thread-sewn or wire-stitched before being covered on an adhesive binder, the speed differences among the machines posed a challenge to their production. So the first plan, along with increased space and installation of more sewing machines, was to boost the adhesive binding capability. Books delivered into a conveyor connected to a trimmer Multiple options The SDR top management explored various options, including a pre-owned Kolbus line that would help streamline the workflow from gathering to three-knife trimming. “We had already seen a few machines in Europe and were in a discussion with Welbound Technical Services to inspect the line and then help commission the same in our factory,” Rajiv Gupta explains. Anil Kumar, the Impel-Welbound head for sales, helped the Guptas and the shopfloor team through each and every step, even though the company was not considering an investment in a Welbound kit. Rajiv Gupta adds, “During PrintPack 2019, we learnt of the separation of the manufacturing arm from Kerala and the front-end headquartered in Mumbai, and that’s when we took a unanimous decision to invest in the Bindwel Freedom > 4K.” Sanjay Gupta adds, “We evaluated the 12-clamp binder from Impel-Welbound during PrintPack 2019 and liked the concept. You can start with the binder, add a book block feeder when you need, add a gathering machine that can also have side stitching, and finally connect it to an inline trimmer. A solution that gave us complete freedom, of effectively utilising the resources — be it capital, space or manpower.” Round-pile cover feeder allows additional stacking Growth plans Rajiv Gupta points out, “We had no doubt in our partner for our growth plans for bookbinding. Here was a person and his company which was willing to help us in any manner, even if it meant getting a pre-owned Kolbus commissioned. Welbound had a clear idea of the challenges faced by book printers. In fact, I think it probably has one of the best after-sales service teams for post-press in India. Plus, its own manufacturing plant in Karnataka. This backing, plus the benefits offered by the 12-clamp binder, made us pick the binder for our new capacity.” Sanjay Gupta adds, “There were teething issues with the new machine in our place. We were moving from a six-clamp which is more forgiving in process issues. Also, we were moving to a system that had the capability to expand in both directions, and demanded that our process delivers inputs that are consistent.” And so, the SDR top management invited Suresh Nair, the Impel-Welbound’s technical director, who is based in Bengaluru. Rajiv Gupta says, “Nair visited us and spent two days in educating us and our operations team about the ‘do’s and don’ts’ and also highlighted a few gaps in process and equipment. The Impel-Welbound team even spent time in adjusting other machines like the thread-sewing machines, so that the binder received consistent inputs.” The right solution SDR believes that it invested in the right solution that can be expanded with gluing options and add-ons before or after the binder. The Bindwel Freedom > 4K binder is capable of producing 4,000 books per hour, has centrally-adjustable twelve book clamps, an infeed and a lay-down delivery that takes the books to an inline trimmer. Impel-Welbound is selling bindery in the Indian and African markets. Some of these are shipped as gathering-binding combination with an in-line Signa gatherer. And a few have opted for PUR gluing in addition to EVA. According to Kumar of Impel-Welbound, the book printers in North India are demanding more throughputs. So far, pre-owned, European equipment have not delivered as per expectations. Most of them operate at half the rated speed and create maintenance issues. Therefore, a new machine that can have modular add-ons is the right tech-option. Key SDR customers are Orient Blackswan (OBS), McGraw Hill and Rachna Sagar. The Guptas are very proud about the fact that they bagged the first prize in excellence in book production from the Federation of Indian Publishers. This was the Sangam Atlas produced for OBS. Five simple tips from Suresh Nair, the Impel-Welbound CTO 1. Inline binders help you reduce the space requirement by 50% and man-power requirements by 70%. 2. Pre-owned binders run at very low operational efficiencies – be it speed, turnaround times or break-downs – turn out expensive even in the medium-run. 3. Per book cost is absolutely important, whether you are servicing an MNC publisher or a government textbook board. It is not the investment cost that matters. 4. Inline binders are less forgiving than the offline solutions when it comes to quality and consistency of the inputs. Be it the quality of pressed and stacked signatures, book block thickness uniformity, consistency and tightness of thread-sewing or conformity of side stitching. But then all these are important for reducing in-process wastage as well as delivering quality output at increased speeds. So if you are waiting for the day when all these inputs improve before you invest in an inline binding solution, then it will be too late. Buy the horse and the process of fitting the cart will automatically follow. 5. It is high time to look at the long term objectives to save costs; be it choosing the right grain direction, making the cover longer than the book block, having regular maintenance plan for your old machines, moving to non-pigmented better quality adhesives, using a high capacity melter while doing thick books, have energy audits done and most importantly, safety first.

Education Stores installs WB@2500 perfect binder

![]() 14 Aug 2020

14 Aug 2020

((l-r) Devendra Pathak and Manoj Kumar Pathak Ghaziabad-based Education Stores have completed the installation of WB@2500, a six-clamp perfect binder from Impel-Welbound. Founded by brothers Devendra Kumar and Manoj Kumar Pathak, the 23-year-old company is an integrated print house with a focus on book printing. They cater to large private publishers as well as government textbook corporations and mostly just-in-time printing. “Tough situations call for tough people to make brave decisions so that the customer is not inconvenienced. We are not used to hiding behind excuses and when our customers needed the right quality products, delivered quickly, we needed the WB@2500,” said Devendra Kumar. Speaking further about the investment and the timing of it (semi-lockdown situation in the region), Manoj Kumar said, “When one of our customers wanted about 15 lakh saddle-stitched books delivered at different locations in India, with a near-impossible time schedule, we gladly accepted the challenge.” The WB@2500 with the maximum speed of 2,500 books per hour is packed with several features including separate side glueing, adjustable ornamental creasing, inline cover feeding, powerful cam based nipping station and delivery among others According to Impel, the new WB@2500 was dispatched from Bangalore, delivered, installed, commissioned and training imparted to the operators – all that under ten days. “This is a new record for us, and maybe the new normal in the coming days”, said Anilkumar Nair, director sales of Impel-Welbound. “We are seeing the demand come back for machines, since May 2020 and we have already shipped six machines to the northern region. Insourcing and quality enhancement are the key reasons for the demand,” he added. “The technical know-how shared by the sales and installation team has enhanced our knowledge of bookbinding techniques. They have helped us to achieve the highest quality of perfect bound books. Many of their suggestions have helped us to rectify the errors in our existing process. Most importantly, with this addition, all books produced are of the highest quality which is giving our clients complete satisfaction and this is a matter of pride for us,” said Devendra Kumar.

Arihant Offset adds Impel-Welbound WB@2500 perfect binder

![]() 26 Aug 2020

26 Aug 2020

(l-r) Anil Jain, Sunil Jain and Navin Jain with the newly installed machine New Delhi-based Arihant Offset has installed a brand new WB@2500 six-clamp perfect binding machine manufactured by Impel-Welbound in Bengaluru. Founded in 1998 by Anil Jain, the offset printing unit located in Nazafgarh Road focuses primarily on large Government tenders, across India, with a specific interest in textbooks. “As some of the jobs that we undertake are of huge volumes, sometimes there is huge pressure on capacities. We also cannot build fresh capacity as some of these jobs are seasonal or once in a while. We have additional print partners in NCR and Mathura who help us in times of such capacity requirements”, said Anil Jain. “We have always met our customer requirements, be it on turnaround times or quantity or fulfilment. Our USP is- be it one thousand books or one million, we will produce and deliver it, anywhere in India,” he added. The sprawling 40000 sqft plant is equipped with a wide range of pre-press and post-press equipment apart from a raft of presses. Talking about some of their challenging jobs, Jain said, “ We are especially proud of a book made for the ministry of agriculture, from design to delivery in 72 hours. There is also a 65 million books order for a textbook corporation, which was delivered in 60 days from the date of order.” “And not to forget when Punjab Technical University wanted six lakh answer sheets within one week, they relied on Arihant to fulfil the order, and we promptly delivered them,” he added. “As they are used to meeting such near-impossible deadlines when they ordered a machine, they wanted it installed within 10 days. We had just done such a task recently for another customer and that gave us the confidence”, said Anil Kumar, director sales of Impel-Welbound. “From the time of discussions, order finalisation to installation, we found the Impel team to be professional. One of the top reasons we opted for WB@2500 is that we wanted to insource some of our critical jobs that are high value,” said Jain. “Apart from the top quality finishing, the MIS feature of the machine was something that impressed us. As we cater to tenders that are time-bound, the information of production and cost parameters on a daily/periodic basis is helping us immensely to track the status of the jobs,” he concluded. This is one of the seven WB@2500 perfect binders installed by Impel-Welbound in NCR region so far, since partial lifting of lockdown in the area since May 2020.